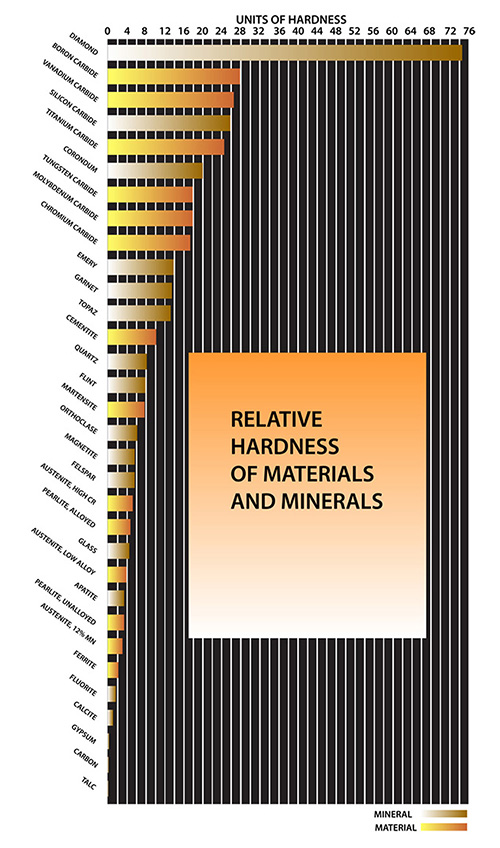

Duritia relativa materiae et mineralium

-

- 1. Adamas

- 2. Bor carbide

- 3. Vanadium carbide

- 4. Pii carbide

- 5. Titanium carbide

- 6. Corundum

- 7. Wolframium carbide

- 8. Molybdenum carbide

- 9. Chromium carbide

- 10.Emericus

- 11. Garnet

- 12. Topaz

- 13. Cementite

- 14. Vicus

- 15. Flint

- 16. Martensite

- 17. Orthoclase

- 18. Magnetite

- 19. Felspar

- 20. Austenite, High CR

- 21. Pearlite, Alloyed

- 22. Vitrei

- 23. Austenite, Minimum alloy

- 24. Apatitis

- 25. Pearlite, sincerus

- 26. Austenite, 12% Mn .

- 27. Ferrite

- 28. Fluorite

- 29. Calcite

- 30. Gypsum

- 31. Carbonis

- 32. Talc

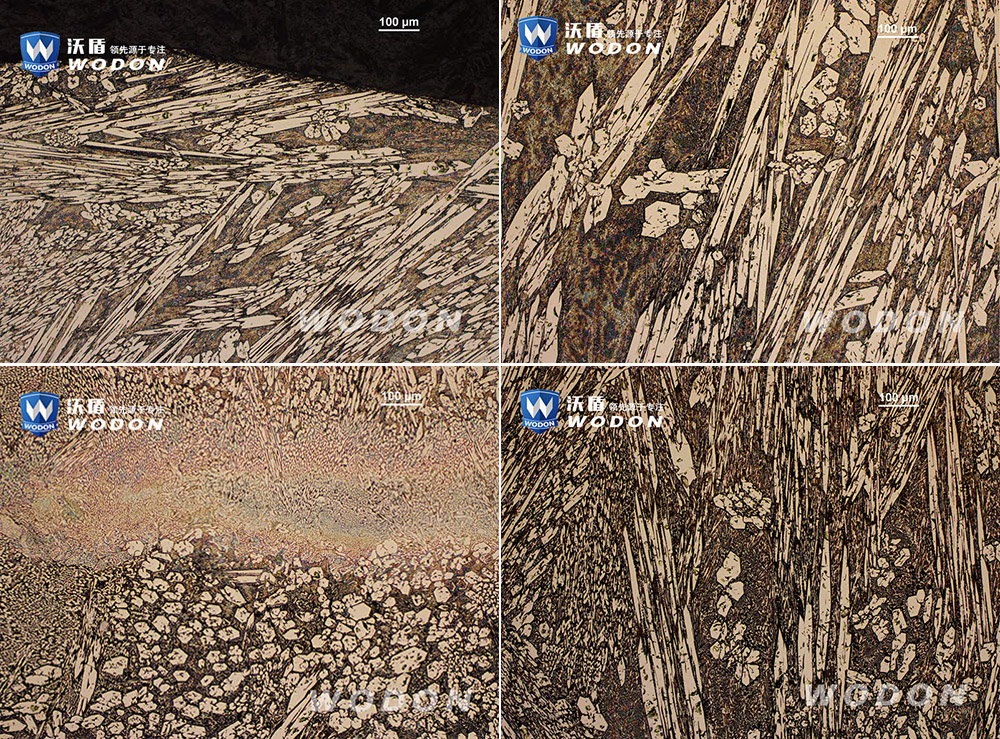

- Wodon speciales sunt in producendo Chromium carbide obductio laminam induendam, submersam arcum technoloy glutino amplectimur, quo plus continet Cr contentum vndique a 25% ad 45%. carbida fractionis voluminis in microstructura supra 50 et maximam duritiem particulae durae est HV1800. ASTM-G65 methode A sub 0.16g.

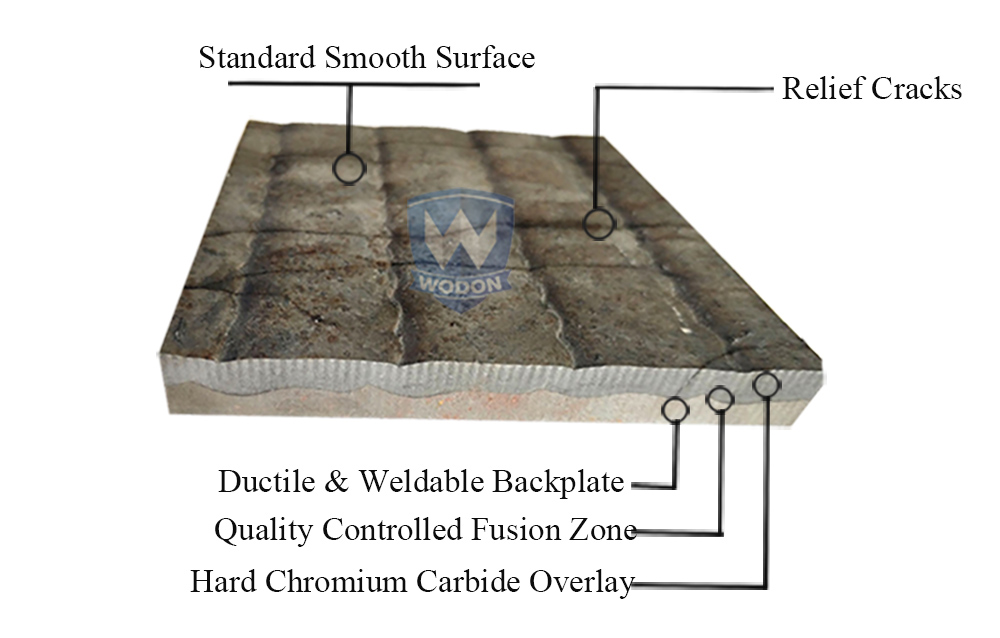

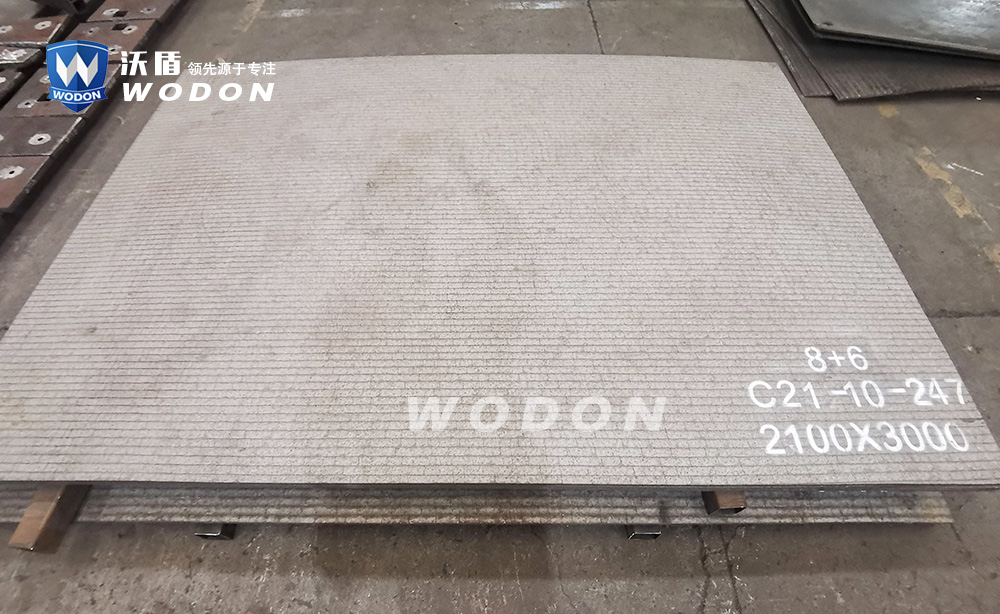

- Chromium Carbide lamina bimetallica:

- Medium/LPrima chalybe +Abrasion repugnant stratis →CHromium carbide bimetallic laminam cum metallurgical compage

- (Q235/Q345B + Chromium carbide deauratum →Chromium carbide bimetallic submersum arcum seu arcum apertum welding

- ars)

- Detail:

- Vestis renitens iacuit chromium carbide duras particulas altam habet. Hae particulae aequabiliter per lavacrum distributa sunt, microstructuram validam creans. Duritia est HRC 58~65and depends on operies crassities.

- Summa ingredientia laminae Wodonis sunt C(%): 3.0~6.0 et Cr(%): 25~45. Haec proportio chemica resultat in magna quantitate cr7C3 chromatis carbidi duris particulis. Micro-duratio (usque ad HV1800) harum particularum per totum iacum praestabit super superficiem togam repugnantem.

- Deauratio et basis laminae compages metallurgicae sunt. Operculum in laminam basim fere 0,8~1.8 mm penetrabit, usque ad 350 Mpa in nostris probationibus attingens.

-

- WD1200 lapsum laminamgravibus abrasione adhiberi potest applicatiadditiones.

- * Chromium carbide deaurabis lapsum repugnant laminam

- * Per demergi arcus glutino technology

- * Compositio chemica: C: 3.0-6.0% Cr: 25-45%

- * Chromium carbide Cr7C3 volumen fraction circa L%

- * Crassitudo vestium renitens iacuit usque ad 50 mm

- * Calor resistentia usque ad DC°C

- * Lager vexillum conterentes aream repugnant 1400*3000mm, 1400*3500mm, 2100*3500mm

- * Potius idipsum lenis

- * Duritia: HRC58-65(650-720HV)

- Eae late utuntur in Mining, Caemente, Potentia, Coal, Portu, Ventus turbines et industria metallica..

-

Post tempus: Sep-27-2021